From Liquid To Stone

Reimagining the design of concrete structures for reuse

Research Project, June 2022 – May 2024

Thesis Advisor: Caitlin Mueller

Work completed in joint collaboration with Jenna Schnitzler

Abstract

Every year, 360 million metric tons of concrete construction waste are sent to landfill in the United States, in large part originating from the demolition of economically obsolete buildings. Meanwhile, global demand for new concrete is accelerating – in 2021, the production of new concrete was responsible for up to 9% of global CO2e emissions, and our dependence on concrete is only expected to rise over the next 50 years.

Concrete’s ubiquity is reinforced by its liquidity; it is simultaneously invisible and ever-present, undergirding global modernization through its cheap, local nature and its ability to take on any form in quick order. However, design with concrete has remained mostly unchanged, with inefficient, irreversibly fused structures cast in place to meet quickly changing programmatic needs, few of which survive longer than 30-50 years. Due to its careless application, concrete is perceived as a low-value material, and is therefore used wastefully, discarded quickly, and usually downcycled. The monolithic and inflexible nature of reinforced concrete structures perpetuate concrete’s culture of obsolescence and demolition.

To meet emissions targets and demand for building, we need to close the loop by developing a circular economy of structural materials. Instead of reusing salvage materials that have already entered the waste stream, this thesis confronts the design of new concrete structures directly, presenting the design of and methodology behind Pixelframe, a precast kit of parts for reconfigurable concrete structures. In a future where buildings are increasingly seen as stockpiles for subsequent reuse, the reinvention of concrete structures is an imperative that presents an opportunity for a new tectonic – concrete is no longer a liquid poured once and cured on site, but instead is a material more akin to stone, retaining value across multiple lifespans.

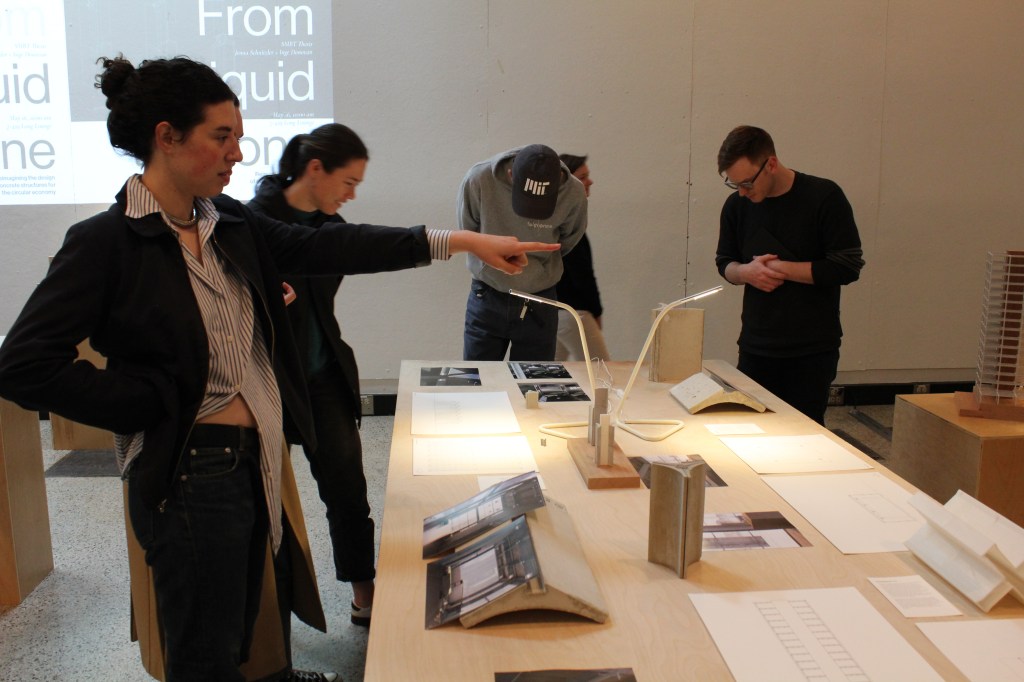

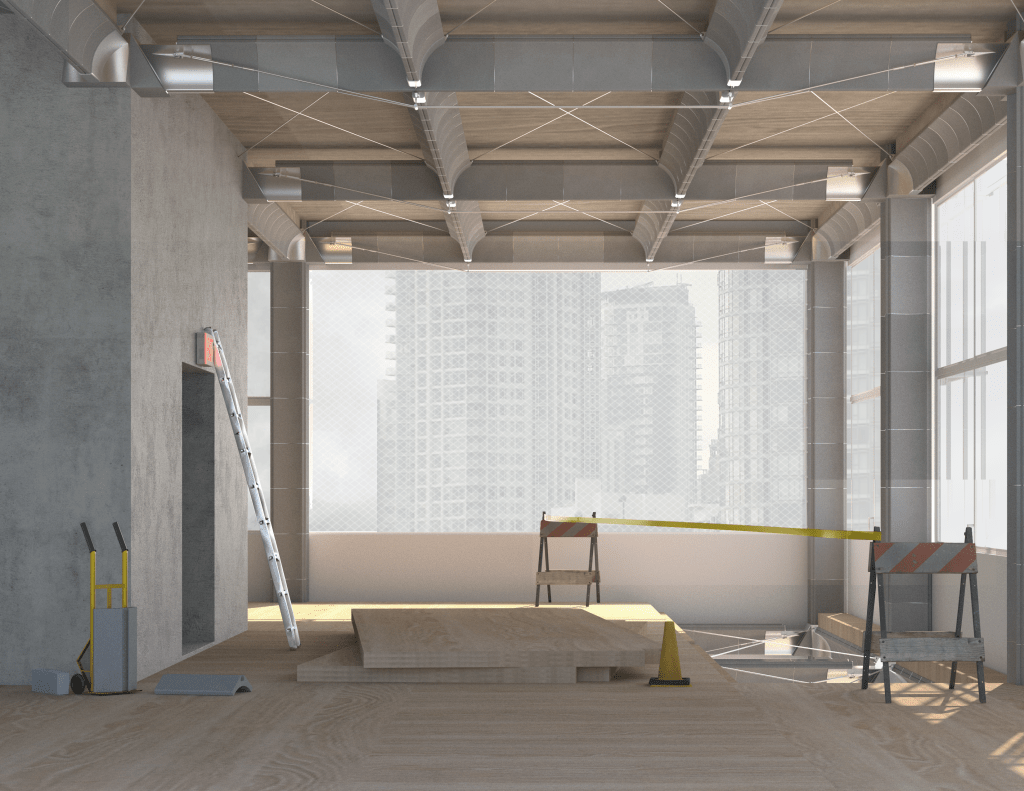

Thesis Exhibition

Foreword

This work began as a studio collaboration in the second year of our Masters of Architecture at MIT, where we explored strategies for joining together reused granite crib stones into temporary structural configurations. What began as an experimental post-tensioned

foundation detail has opened out into a

hugely productive line of inquiry into the shape, role,history, and performance of concrete in our structures today, interrogating how concrete could transcend

the paradigm of liquidity and be discretized into smaller, reusable precast modules, breaking apart the monolithic structure into smaller modules that can be valued and passed on.

From the design of a single, efficient precast concrete beam, this project has enabled exploration across multiple fields, scales, and disciplines as we discover the vastness of the implications of redesigning how to build with concrete. In the circular economy, not only are material efficiency and reuse potential fighting for precedence, but aesthetics are too, essential for technology uptake and for maintaining value over the course of many lifespans. In this thesis, we explore the relationship

between engineering, industry, and design, finding balance in a structural system designed for reuse.

Narratives of Reuse

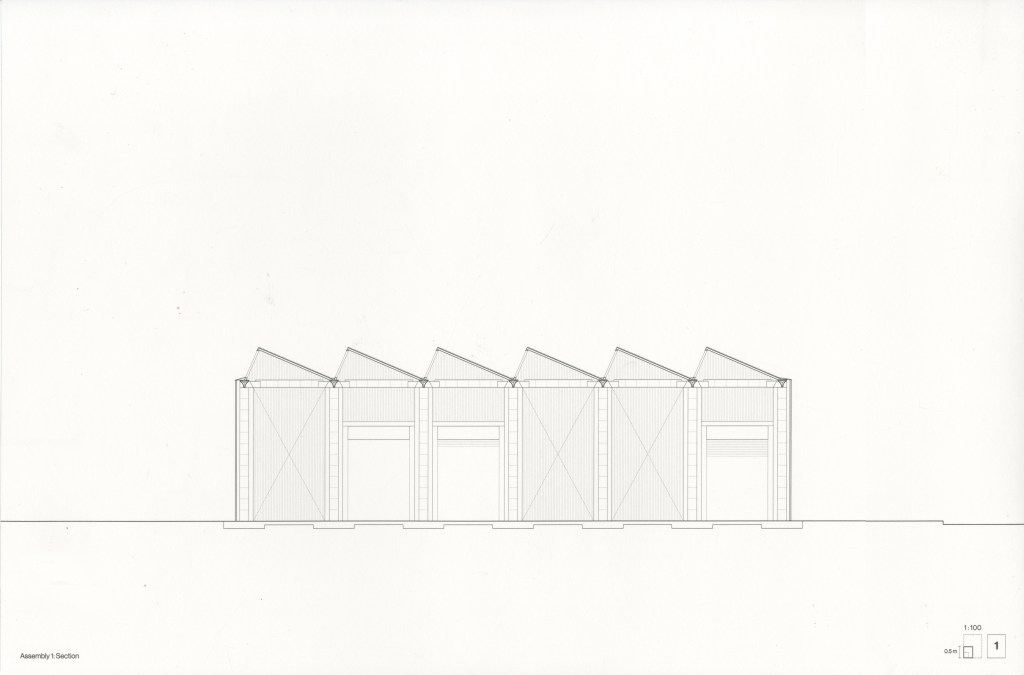

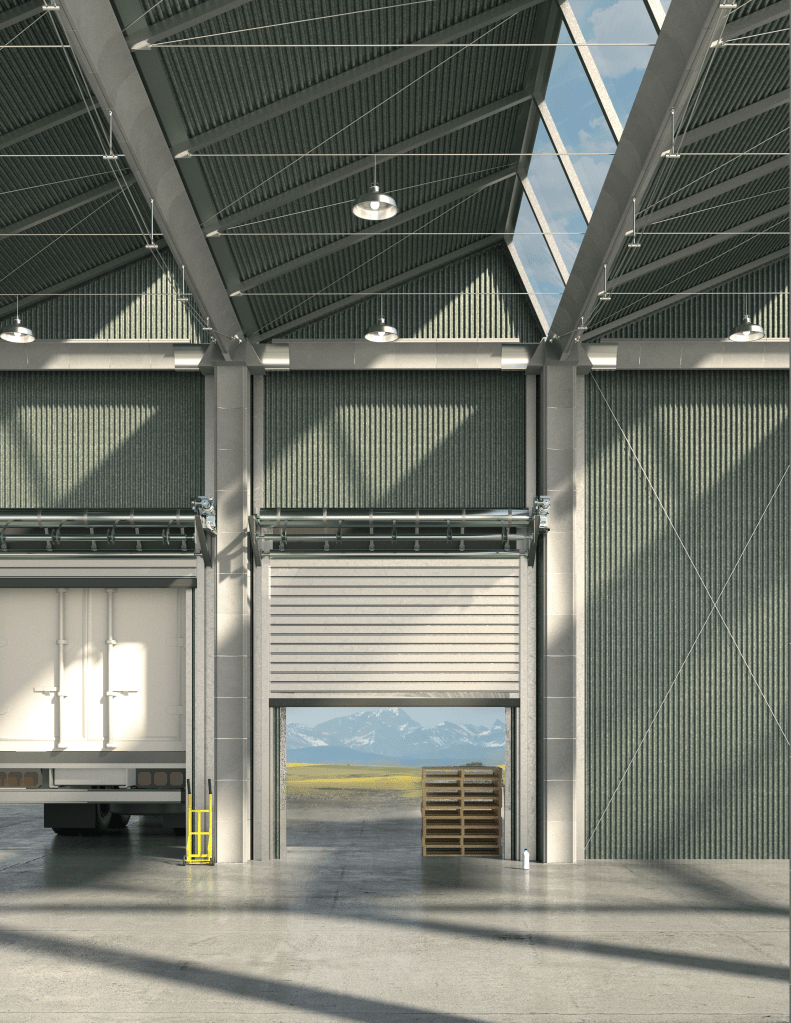

In the fall of 2024, 1,782 pixels were manufactured

for the construction of a warehouse on the outskirts

of Edmonton, Alberta. With the land slated for the

construction of a large residential development in

the near future, the owners of the land sought out

a constructive system that could serve the purpose

of a long-span, high-clearance industrial space for a

term of roughly a decade, and could subsequently be

disassembled and reused, avoiding the cycle of building

and demolishing that was overwhelming landfills with

low-value building materials that could not be reused.

The warehouse was in operation for nine years before

deconstruction crews arrived to demount the beams

and columns, which were unbolted and lowered to

the ground with cranes. They were disassembled,and

subsequently stacked neatly into a truck for transport

to a storage facility.

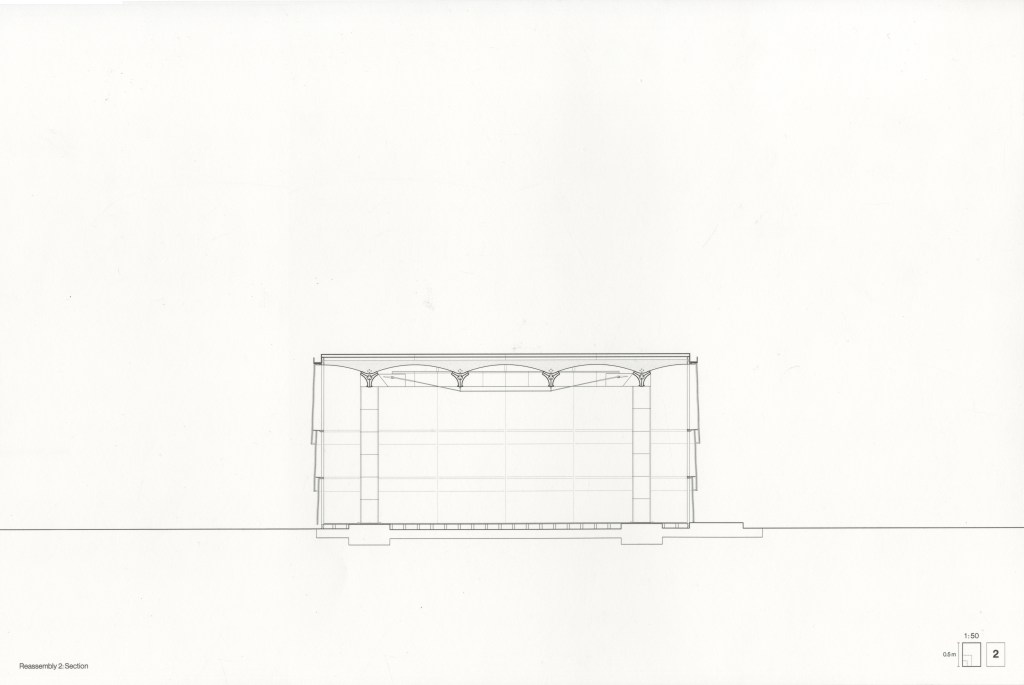

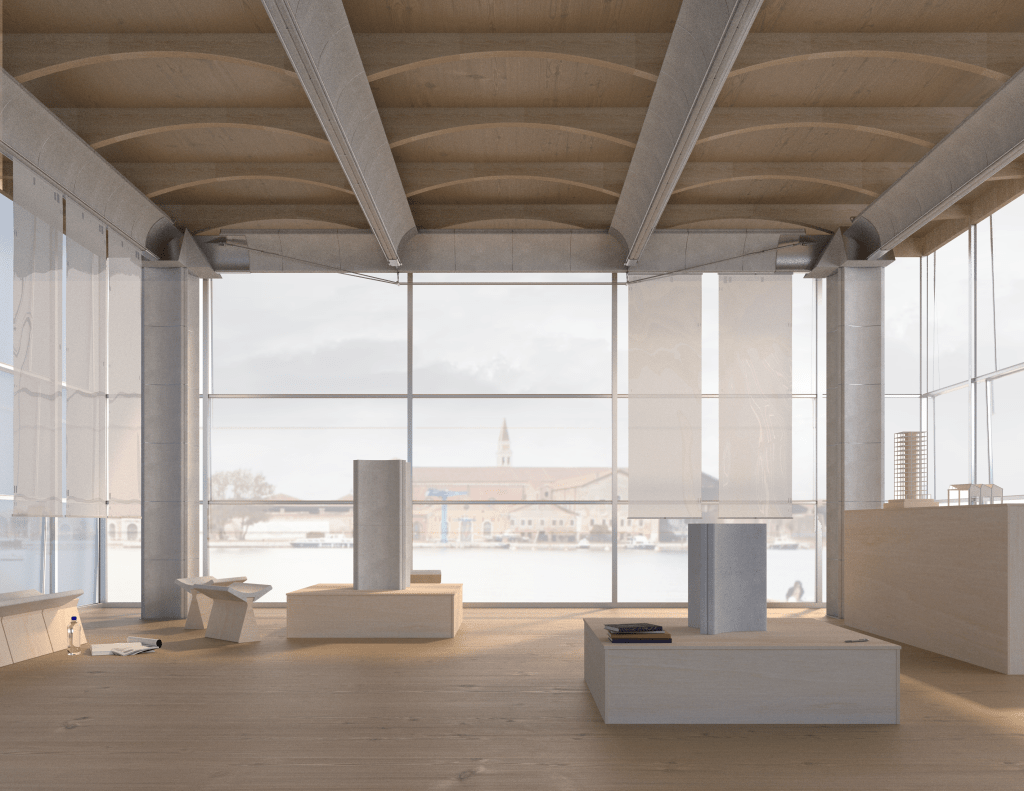

Ten years after the introduction of the system, an

exhibition was planned to showcase the success of

design for disassembly in the building sector. To house

this exhibit, a small pavilion structure was designed

to be assembled using only second- and third-life

structural modules, using the material passports

associated with the pixels to assign them to locations

in the new structure. The pavilion has a CLT roof that

was supported by glu-lam beams, whose convex shape

matched the concave top of the Pixelframe spanning

elements. New intermediate plates were designed

to serve as bolted connection points for the glu-lam

members, allowing the structure to resist lateral loads.

Inside the pavilion, visitors could participate in the

disassembly and reassembly of structural modules, and

could read about the structure’s history – its parts came

from diverse locations and previous uses. Participation

in the modules’ pasts and futures de-anonymized

them, highlighting both their material origins and

uniquely local nature, layering cultural value on top

of their structural value as load-bearing members. The

exhibition lasted for several months, after which the

pixels were quickly re-purposed for a new building – a

large, ambitious adaptive reuse project in Vancouver,

British Columbia.

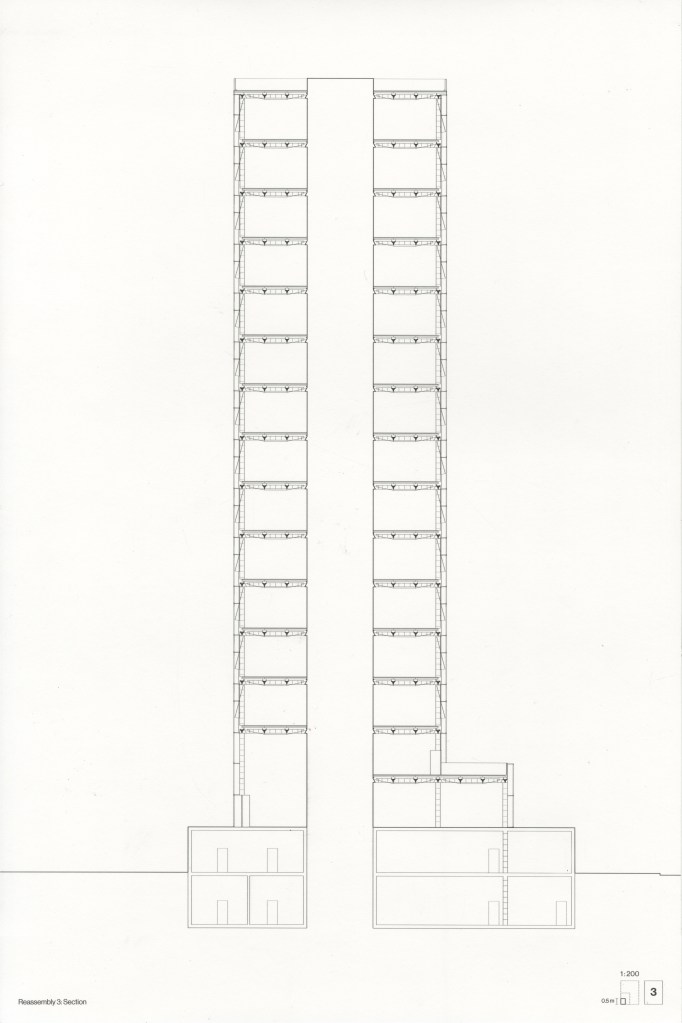

The iconic Empire Landmark Hotel in Vancouver had

been slated for demolition for many years— the fortytwo

storey concrete building was Vancouver’s thirdtallest

structure that had become economically and

physically obsolete. After much negotiation, it was

decided that as much of the thick shear core, which

housed an egress stair, two elevators and various other

utilities, and the foundation should be saved, as they

were still structurally viable. The partitioning walls

and concrete facade were carefully deconstructed,

leaving only the core. Construction work began, with

lintels grafted to the core to receive the Pixelframe

beams that connected the new structural system to the

old one. The gravity frame breathed new life into the

building, allowing for the construction of a naturallyventilated

double-skin facade with expansive views

of the city.

The introduction of a new framing system

raised the floor heights, to have one floor for every 1.5

original floors. This would not have been possible with

new concrete, as the province had strict carbon taxes

per square meter of new construction. However, with

reused concrete structural modules and an adaptively

reused shear core and foundation, the new building’s

emissions came only from the steel connectors, the

facade system and the interior finishes.

The structure was transformed into an office building,

with the interior fitted out with cross-laminated timber

floor slabs that were dry jointed and demountable.

Occupants could enjoy bright, well-lit interior spaces

that were characterized by the connection between

the adapted concrete core and exposed concrete

frame, with plumbing and electrical systems exposed

for easy maintenance and repair. Here, concrete—a

material that when it is perceived, is usually deemed

inert and anonymous—was transformed into a one

with a complex history and past lives, transforming

a monolithic building destined for landfill into a

semi-permanent configuration of reusable structural

elements.

112

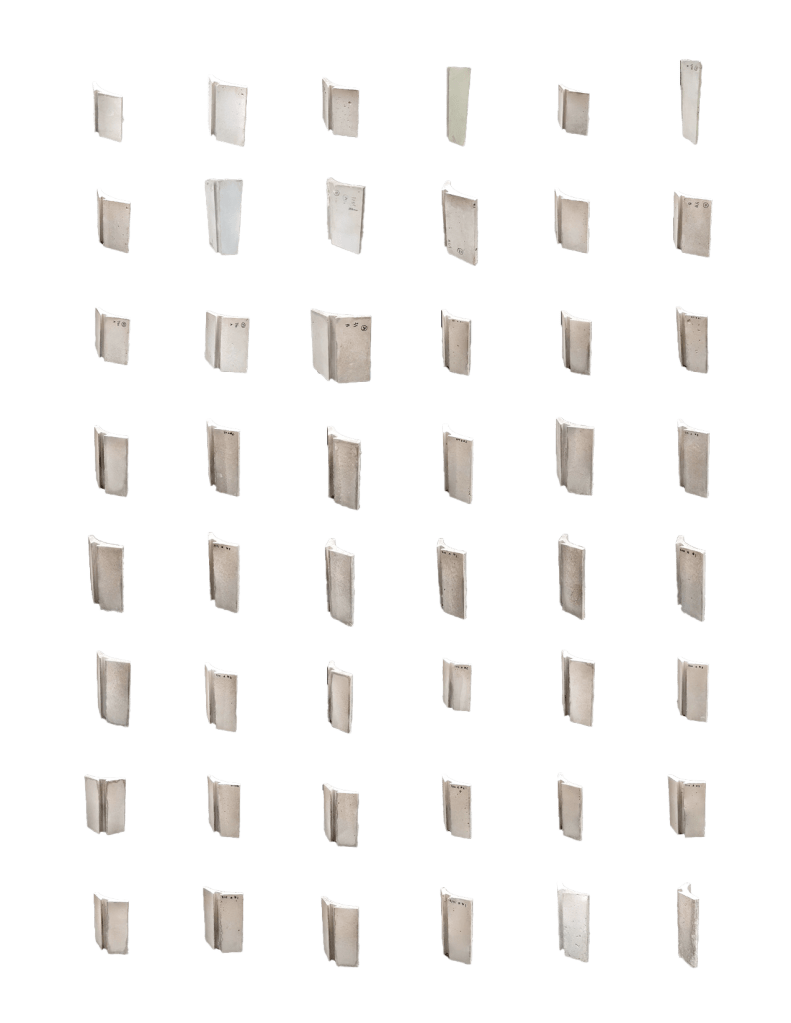

Model Photos

System Description

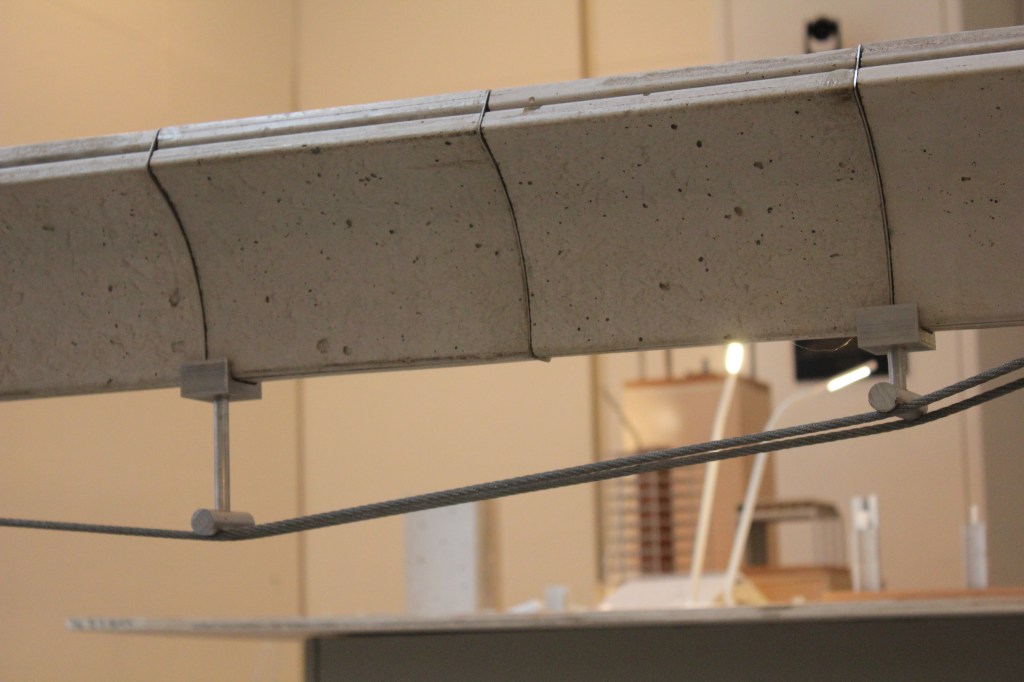

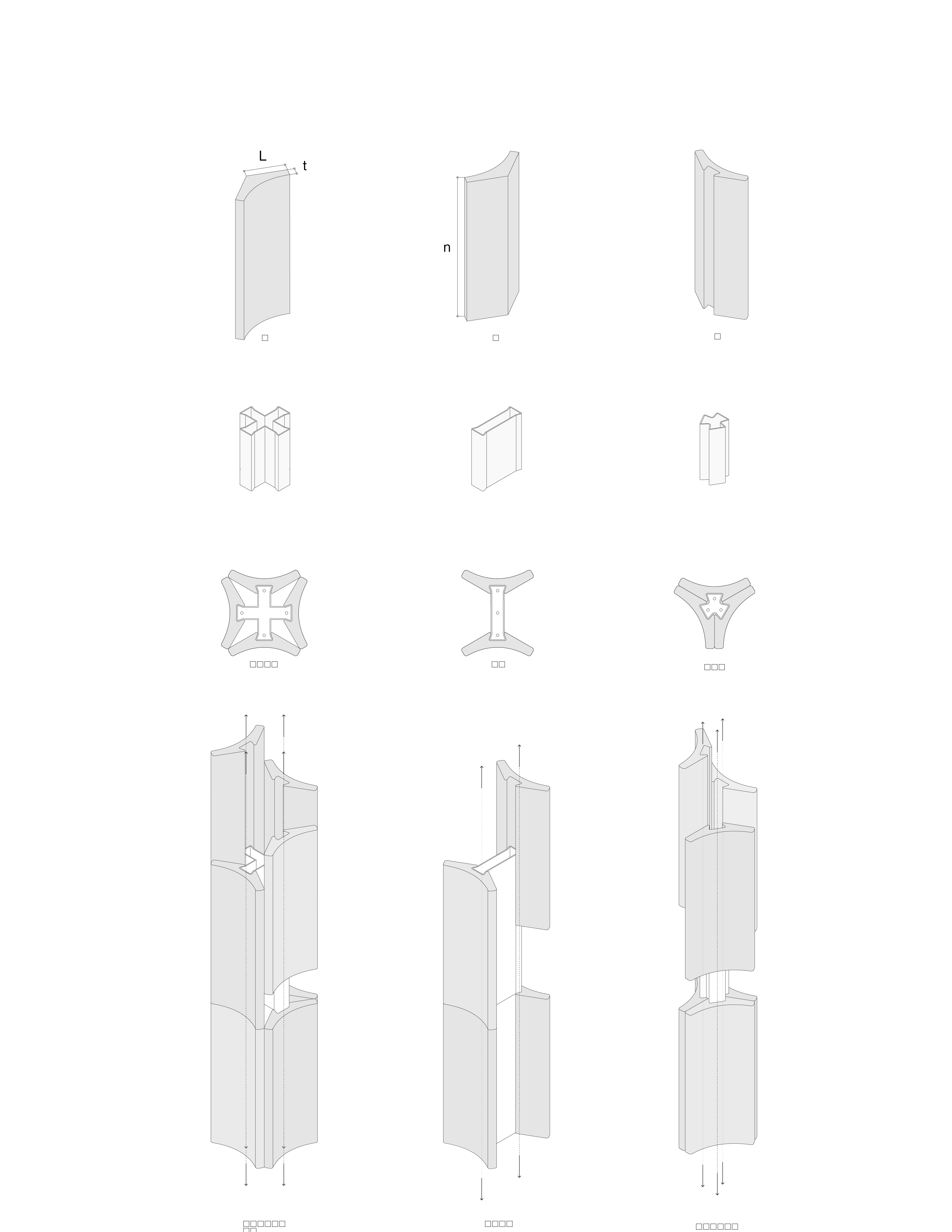

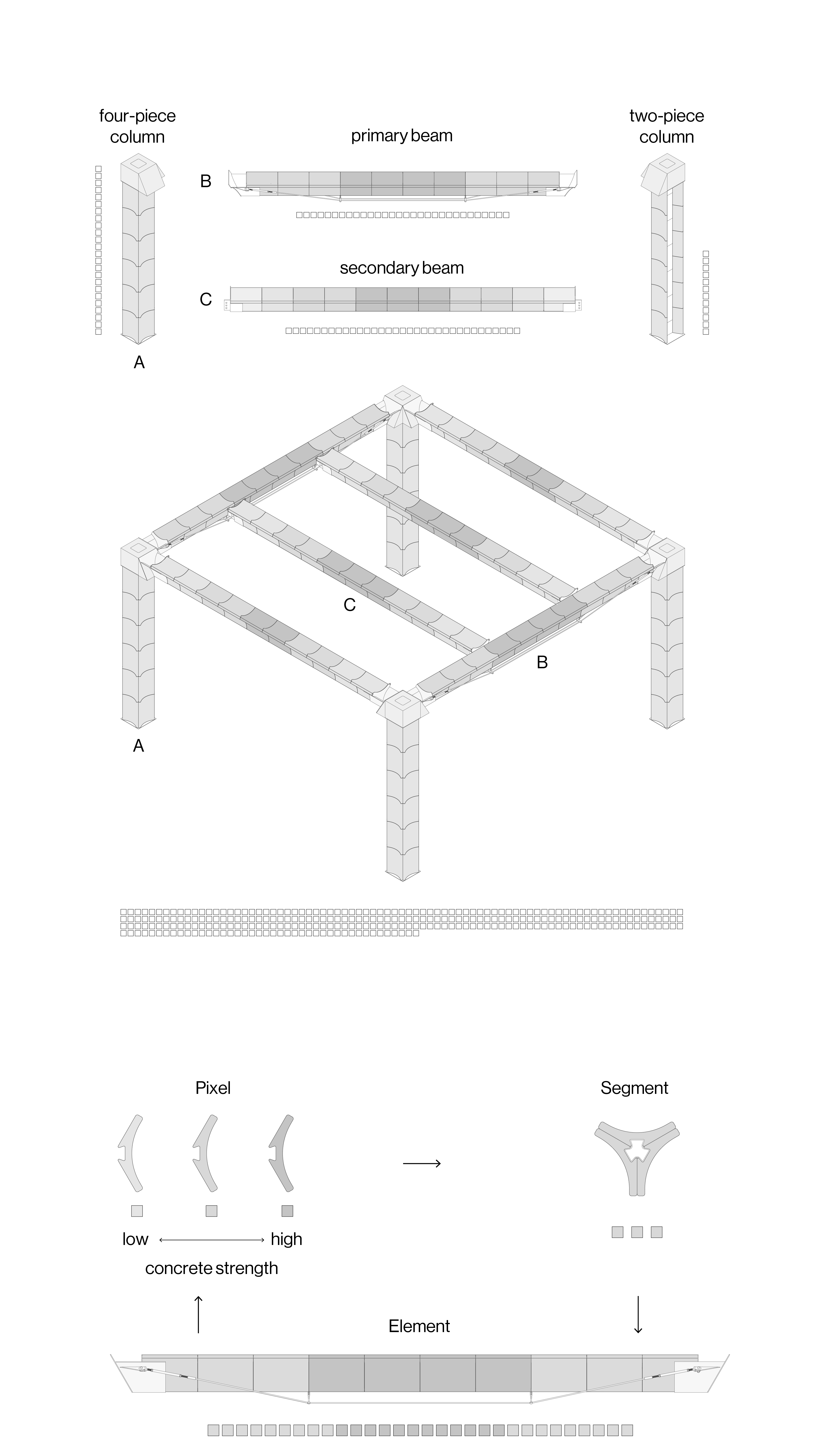

Pixelframe is a demountable precast structural framing system designed in segments designed to improve reuse potential while maintaining flexibility and efficiency. The system reduces the demand for new concrete through the use of a unique discretized geometry, which is 60% more materially efficient than conventional construction in reinforced concrete.

Fiber reinforced structural modules, called pixels, are configured into diverse cross-sections, and aggregated into beams and columns that make up structural frames. While conventional reinforced concrete elements are designed for extremes, the discrete nature of the base module allows for variation in cement content along the length of the element. As cement content is positively correlated to embodied carbon, this means high-strength, high-carbon modules can be distributed only where they are needed in the structure. All connections in the system are dry-jointed for damage-free, rapid assembly and disassembly, using unbonded post-tensioning to ensure monolithic behavior of segmented elements.

Pixelframe is designed for a future where structures are designed to be both efficient and fully integrated into a circular economy of building materials. By creating a smart kit of traceable, high-efficiency, simple-to-reuse parts, the system facilitates the role of buildings as material banks for future reuse, helping close the loop of building construction.

Work done in collaboration with Caitlin Mueller, Jenna Schnitzler, Keith Lee, and Emily Liu.